Mobile frames rack: Motorised

Efficient storage and handling of heavy metal sheets or metal sheet rest pieces

- Automated mobile frames, creating an aisle when moved

- Compact storage method

- Clear structure and overview of all metal sheets – rest pieces

- Only 1 person required for the handling

- Time saving, less labour time needed

- Safe and easy handling of the heavy metal sheetss

This sheet rack is operated electrically or with a crank. Searching for a mobile sheet rack with manual operation? Then visit our page on

mobile frame rack: manual operation.

Fast and easy access to your metal sheets, rest pieces and other sheet materials.

The electrical mobile frame rack is the most space-saving method when you want to store a bigger volume of heavy metal sheets. The mobile frame rack with automated electrical moving frames is compact and provides a good overview of all you metal sheets. The mobile frames are provided with wheels and a lever. By pulling the lever you can mark the position where the aisle should be created. The mobile frames are positioned on 2 parallel rails. The moving mobile frames create an aisle for easy access to the selected metal sheet. It's a safe and secure handling method.

For the control of the mobile frame rack, there are 2 possibilities:

- An entirely electrical system, where the frames slide open automatically after pushing the control button.

- A hydraulic method to move the frames with a crank. This model functions in the same manner as the electrical mobile drawer frames, but the electric box is replaced by a crank. (upgrade to electric version is possible)

If, however, you prefer a completely manual control, then visit our page about the Manual control.

3D-videos: storage of heavy sheet metals in the mobile frames rack: electrical control

Every mobile frame is equipped with a treadle. When pressing the treadle and then the activation button, the frames will move to the end position. This creates an aisle at the position where the treadle was pressed, i. e. the selected position.

During this displacement of the frames, the operator can prepare for the handling itself. As soon as the operator enters the aisle, all frames will automatically stop moving, due to sensors. The handling can now safely and comfortably take place.

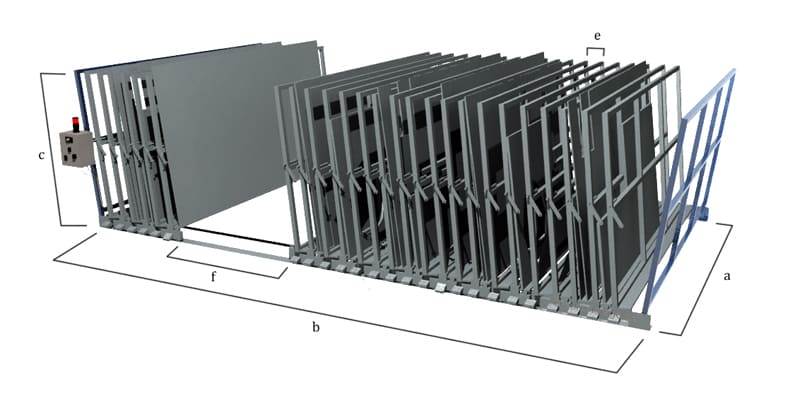

Specification of the mobile frames rack: motorised or hydraulic with crank

| MOTORISED MOBILE FRAMES RACK | |||||||

| Sheet dimensions | Type | Length (a) | Height (c) | Loading space (w) | Capacity drawer | Quantity of drawers | Rack width (b) |

| 48" x 96" | RMM 125 | 5,5” | 5500 lbs | 10 - 25 | 87”-263” | ||

| 48" x 120" | 5.5” | 5500 lbs | 10 - 25 | 87”-263” | |||

| 60" x 120" | RMM 150 | 5,5" | 5500 lbs | 10 - 25 | 87”-263” | ||

| 60" x 144" | 5.5” | 5500 lbs | 10 - 25 | 87”-263” | |||

| 72" x 144" | RMM 200 | 5.5” | 5500 lbs | 10 - 25 | 87”-263” | ||

Attention: if you choose a control with crank version, there is a maximum of 25 frames for 1 configuration!

Hydraulic version with crank!

The hydraulic version works with a crank to move the mobile frames. The mobile frames move on 2 parallel rails and create an aisle at the position you have selected by pressing the treadle.The frames will move to the end position when you rotate the crank. Then you can safely enter the aisle for easy handling.

| MOTORISED MOBILE FRAMES RACK: LIGHT VERSION | |||||||

| Sheet dimensions | Type | Length (a) | Height (c) | Loading space (w) | Capacity drawer | Quantity of drawers | Rack width (b) |

| 2000 x 1000 mm | RMM 100 | 2030 mm | 1130 mm | 140 mm | 3000 kg | 10 - 35 | 3570 - 9195 mm |

| 2500 x 1250 mm | RMM 125 | 2530 mm | 1120 mm | 140 mm | 3000 kg | 10 - 35 | 3570 - 9195 mm |

| 3000 x 1500 mm | RMM 150 | 3030 mm | 1330 mm | 140 mm | 3000 kg | 10 - 35 | 3570 - 9195 mm |

| 4000 x 2000 mm | RMM 200 | 4030 mm | 2150 mm | 140 mm | 3000 kg | 10 - 35 | 3570 - 9195 mm |

| MOTORISED MOBILE FRAMES RACK: HEAVY VERSION | |||||||

| Sheet dimensions | Type | Length (a) | Height (c) | Loading space (w) | Drawer capacity | Quantity of drawers | Rack width (b) |

| 6000 x 2500 mm | RMM 600 | 3030 mm | 2200 mm | 180 mm | 6000 kg | 10 - 35 | 3570 - 9195 mm |

| 6000 x 2500 mm | RMM 600 | 3030 mm | 2200 mm | 180 mm | 12000 kg | 10 - 35 | 3570 - 9195 mm |

If you would like to learn more about the dimensions and prices, contact us.

For deliveries in the UK, please visit our english website Eurostorage Systems.